Project Summary

FIBRE proposes an environmentally sound catering package in line with international regulations which is achieved by combining lightweight reusable recycled Carbon Fibre dishes with compostable packaging and an online meal pre-booking service.

Design Process

This project was guided by the Double Diamond design strategy. The process was particularly informative in helping consider a wide range of concepts and design directions and then refining the concepts to create a cohesive design concept and prototype.

DISCOVER

Why Serve Food In-Flight?

The quality of inflight service is an important influencing factor on a passenger’s airline choice. Airlines use their passenger food service package to gain a competitive edge. In a bid to please a wide range of passenger needs, airlines will often overstock aircraft with food.

The Waste Problem

https://www.cabinwaste.eu/en/zero-cabin-waste-project/

https://www.cabinwaste.eu/en/zero-cabin-waste-project/

https://www.cabinwaste.eu/en/zero-cabin-waste-project/

Aviation’s contribution to global pollution through its emissions has led to increasing criticism. People, however, are less aware that catering is the industry’s hidden polluter.

Market Research and Expert Interviews

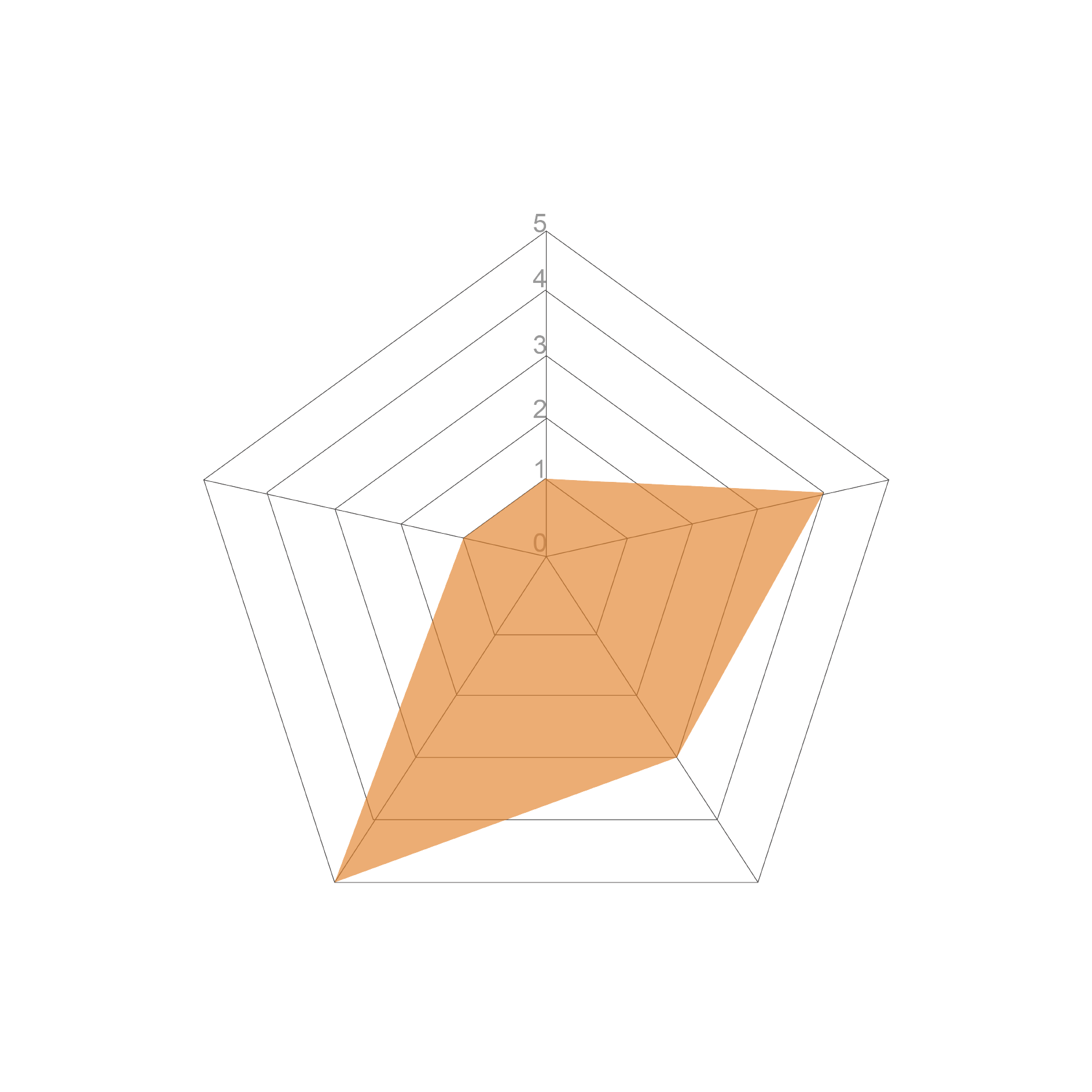

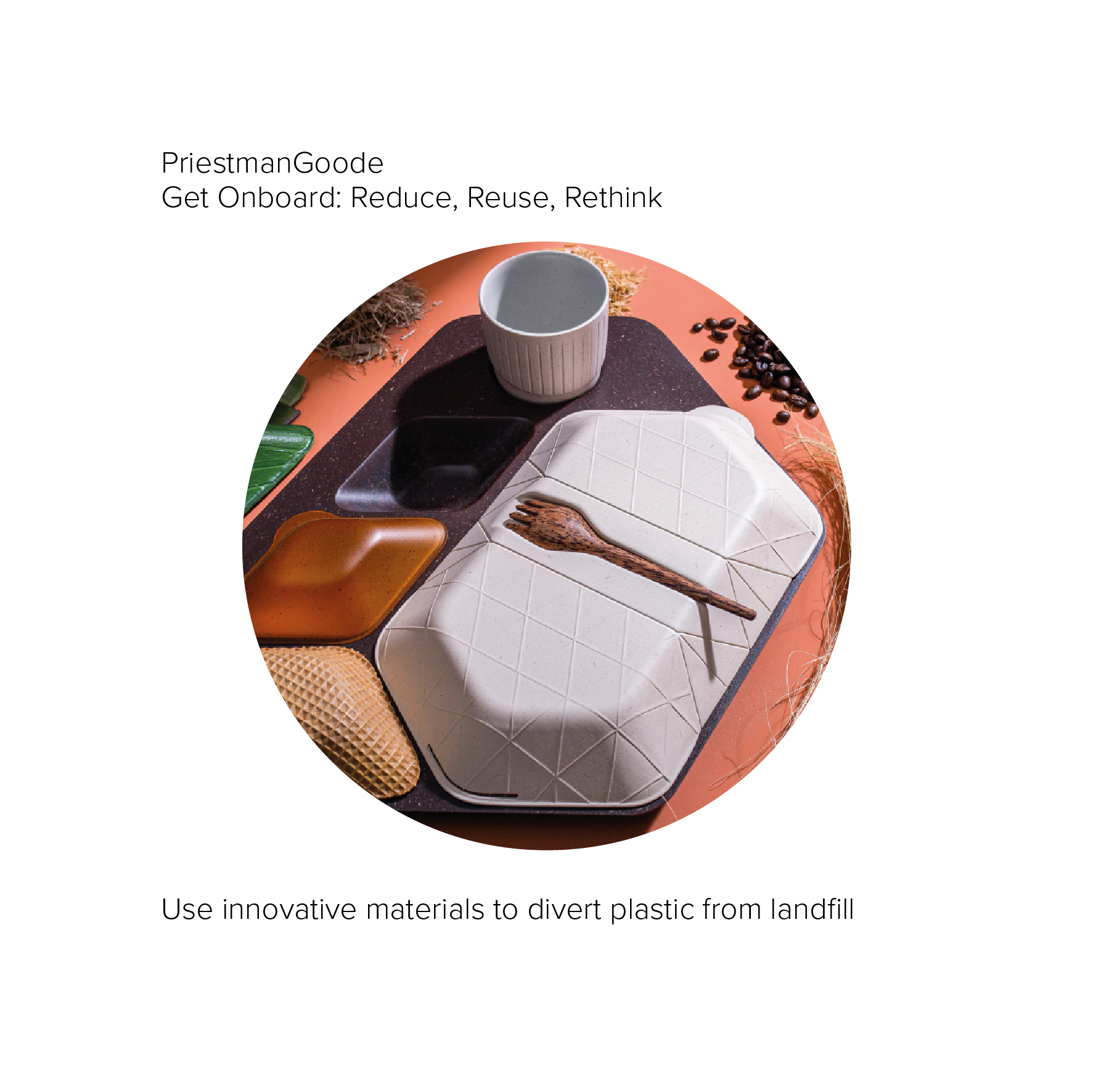

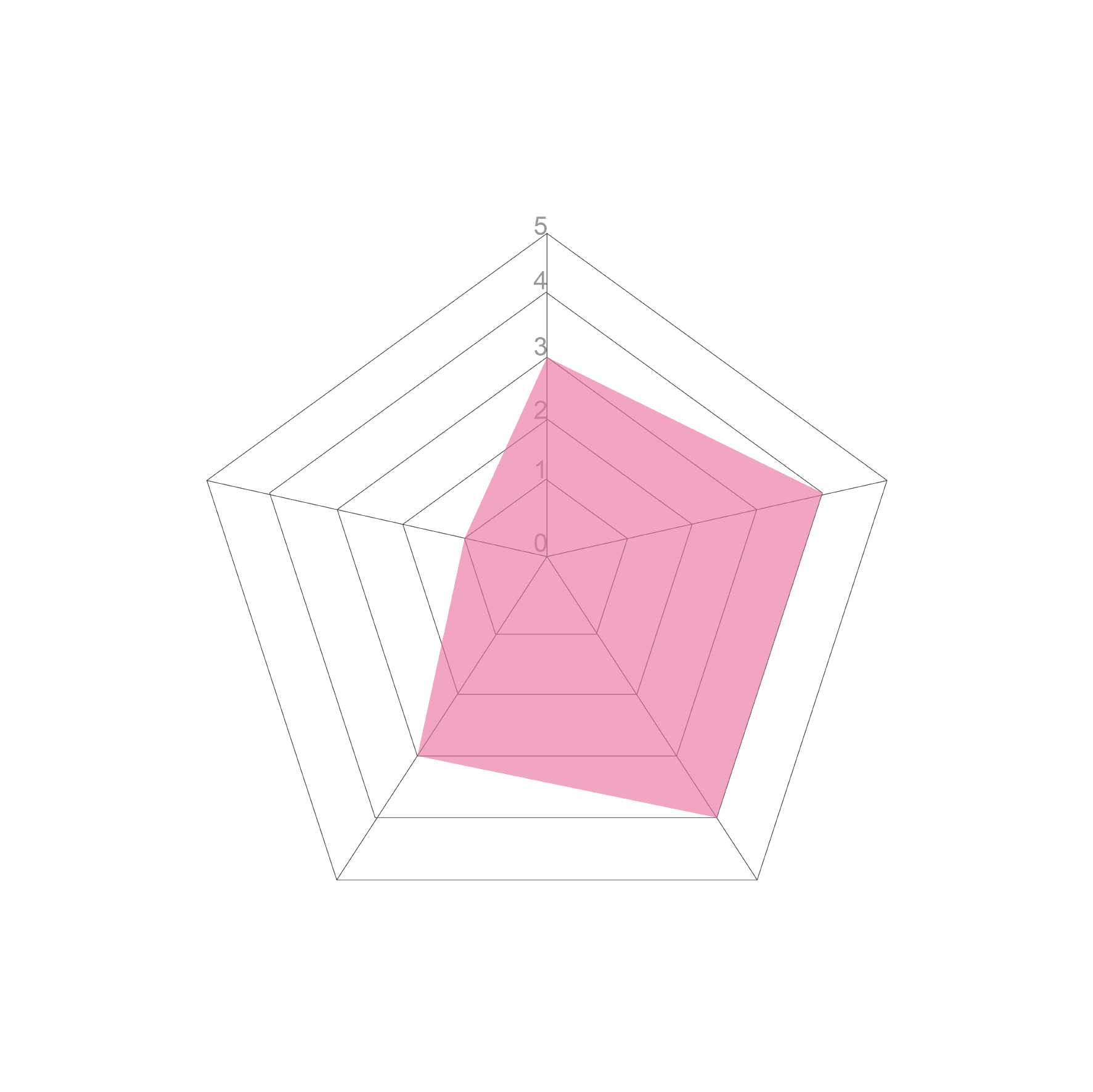

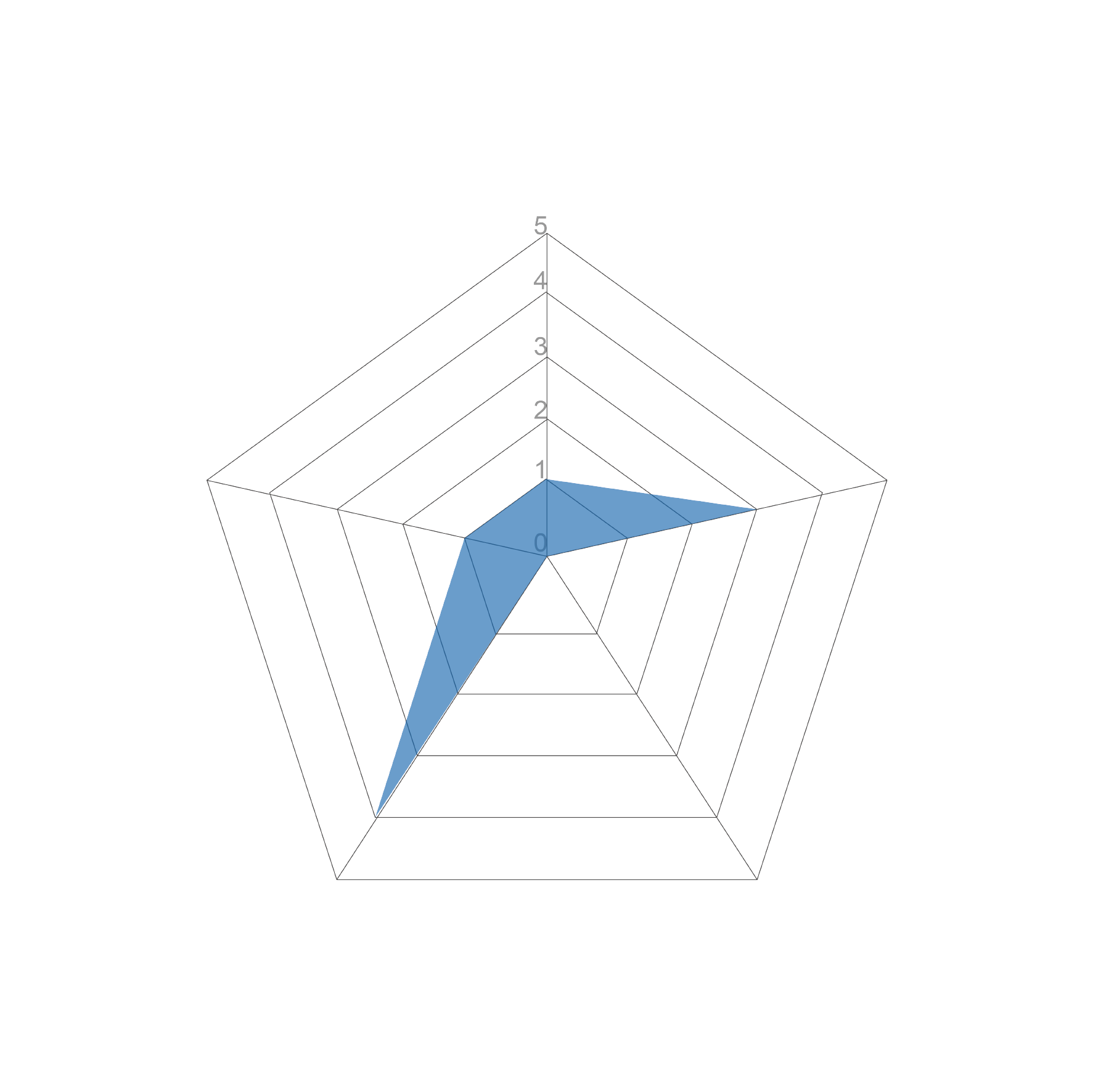

Market analysis was conducted of existing and conceptual products which improve the environmental performance of in-flight meal service. A number of products were rated on their effectiveness of Cost Savings, Reusability, Weight Reduction, End of Life Consideration and Passenger Empowerment.

Two industry experts with experience designing in-flight meal services for airlines were interviewed to aid the evaluation of existing products and the generally insight gathering process.

https://www.dezeen.com/2019/09/16/priestmangoode-sustainable-air-travel-plastic-design/

https://runwaygirlnetwork.com/2014/11/12/qantas-enjoy-big-benefits-meal-tray-removal/

https://www.telegraph.co.uk/travel/news/hi-fly-airline-first-to-ban-single-use-plastic-on-flights/

https://www.businessinsider.com/new-virgin-atlantic-meal-trays-2014-6?r=US&IR=T

DEFINE

Design for Sustainability

A number of design for sustainability methods were considered in the problem definition and Initial idea generation stages of the process.

These included material and product innovation strategies and more broadly, service and spatio-social considerations.

In addition to the above strategies, the Design with Intent toolkit was used to consider how design could influence behaviour.

Problem Statement

How can design be used to reduce the amount of food waste produced and improve the environmental performance of the the packaging materials that will inevitably become waste.

Material Innovation

Research into a lightweight material for a reusable container led to recycled Carbon Fibre and the issues surrounding waste Carbon Fibre

Aircraft manufacturers are increasingly using Carbon Fibre as a construction material because it is lightweight and strong. This leads to large quantities of manufacturing waste and an issue at the end of life of aircraft. Without intervention, current aircraft recycling rates could drop from 97% to below 50% when next generation aircraft start to retire.

New research into recycling processes has allowed the production of a Recycled Carbon Fibre material. This new material can be used to produce extremely lightweight components for non-critical strength components such as a meal tray.

Design Direction

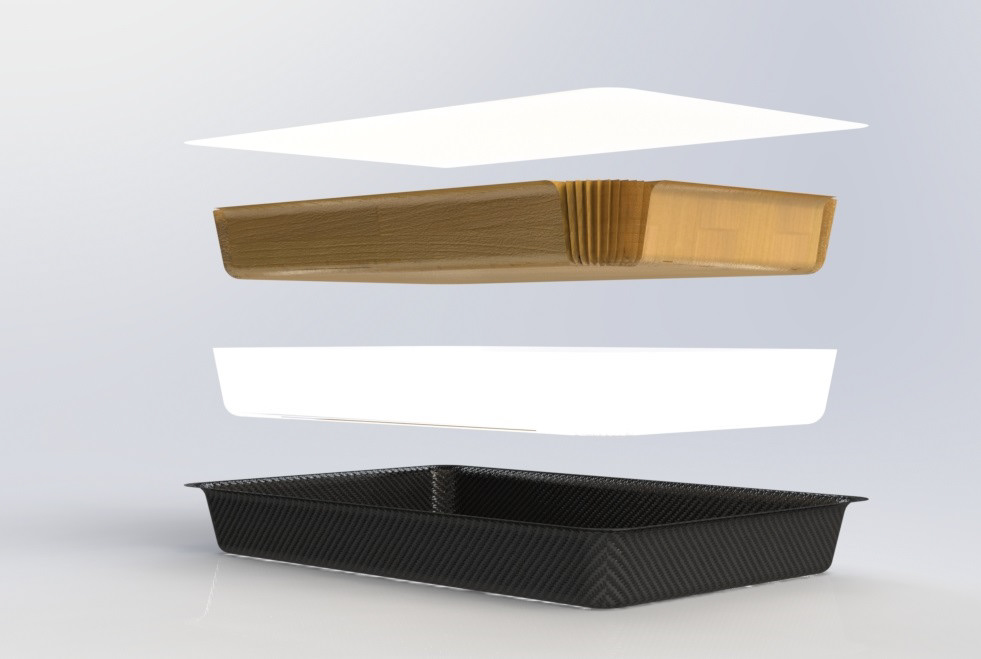

The design will make use of innovation in material design to produce packaging with the following sections:

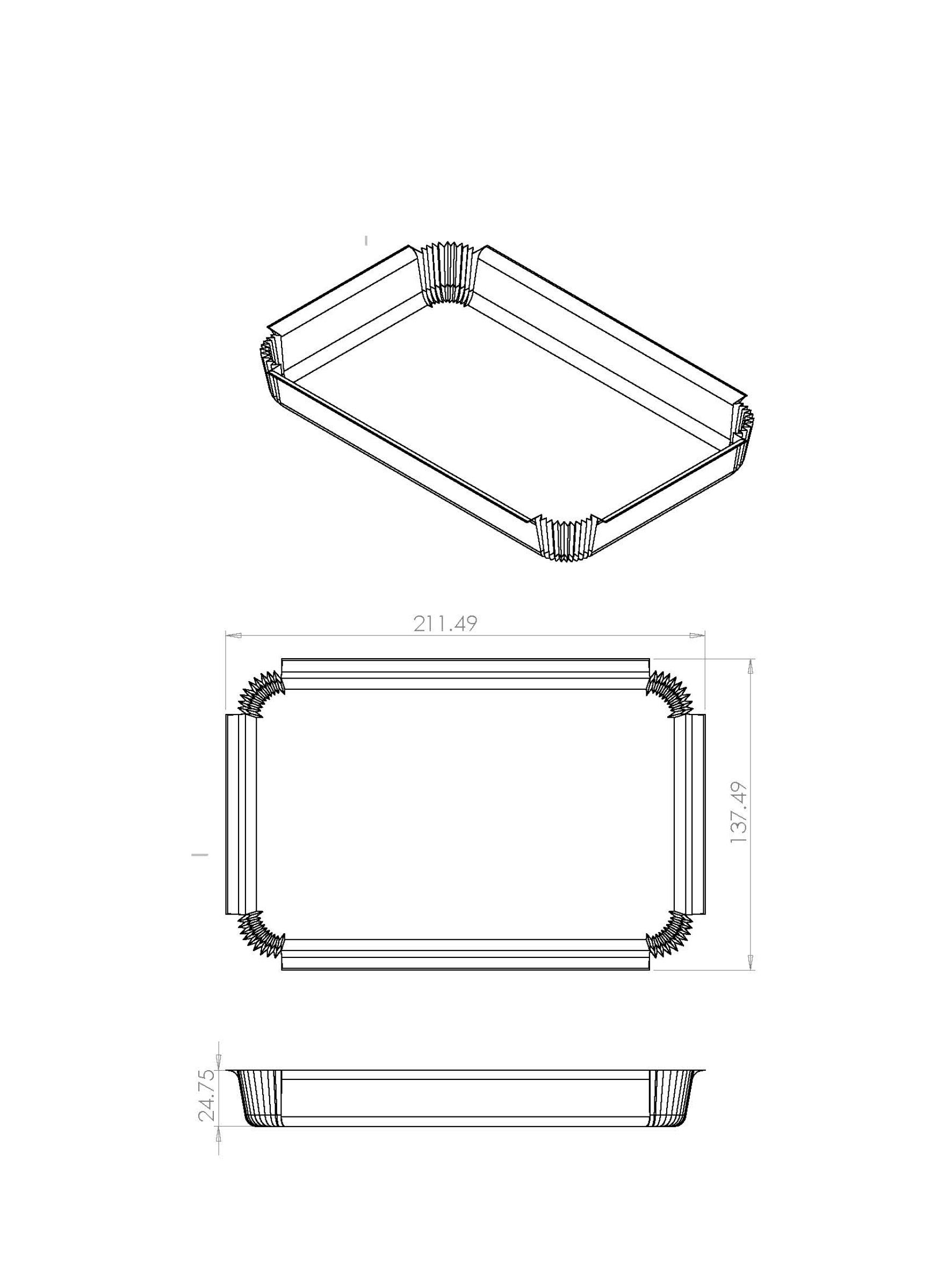

A sealed compostable food contact layer which can be disposed of in a sustainable manner given the current restrictions.

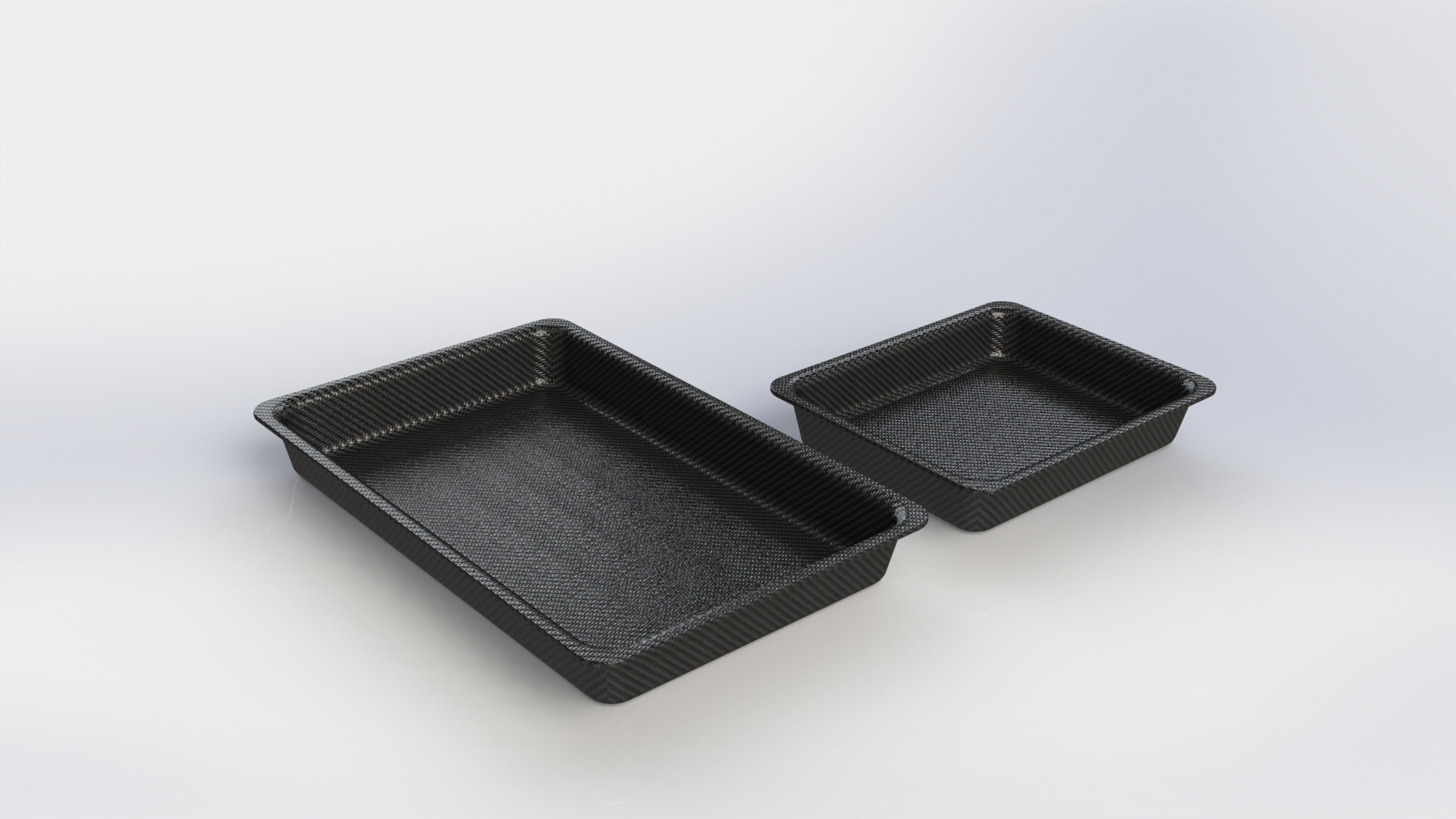

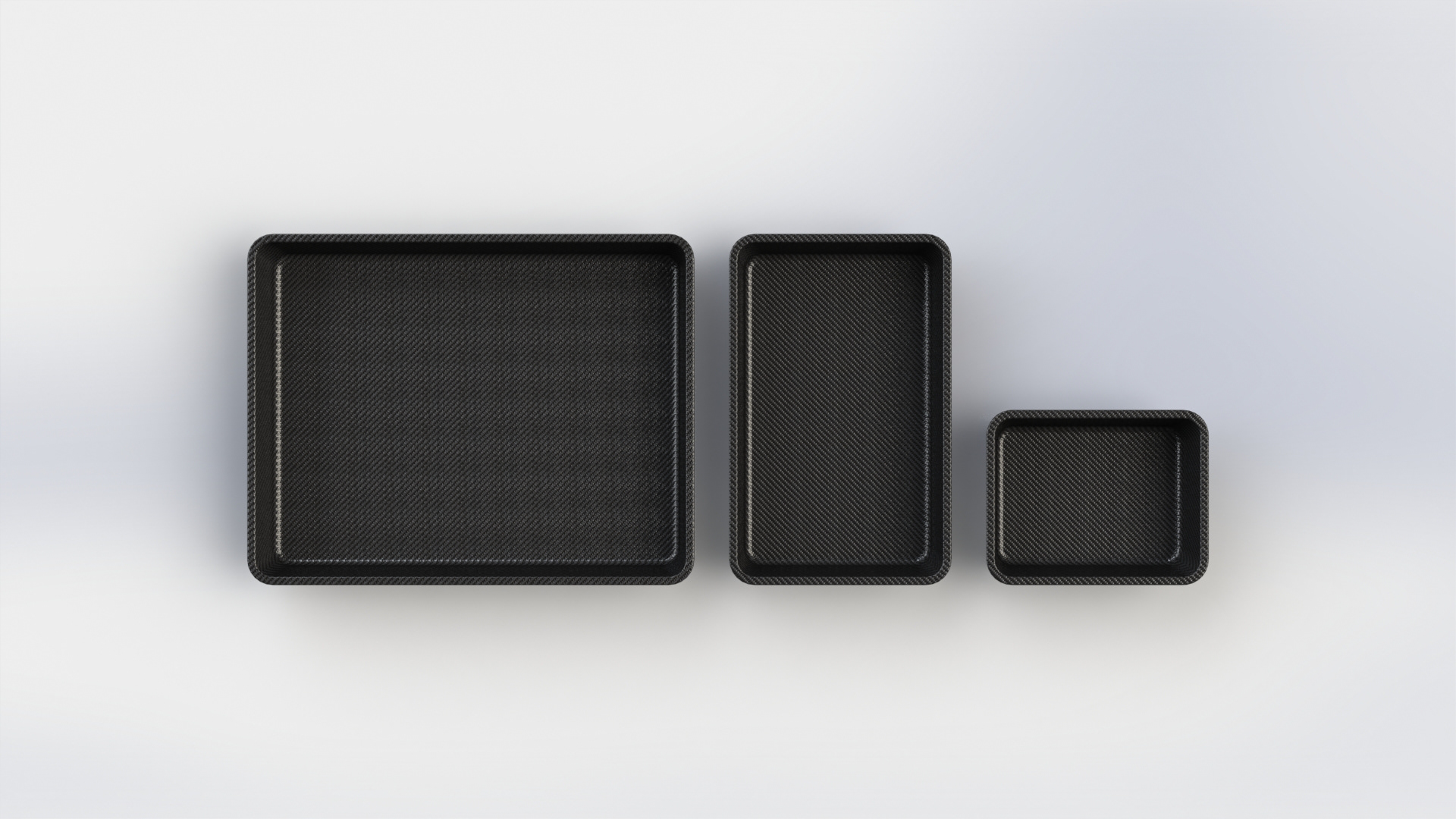

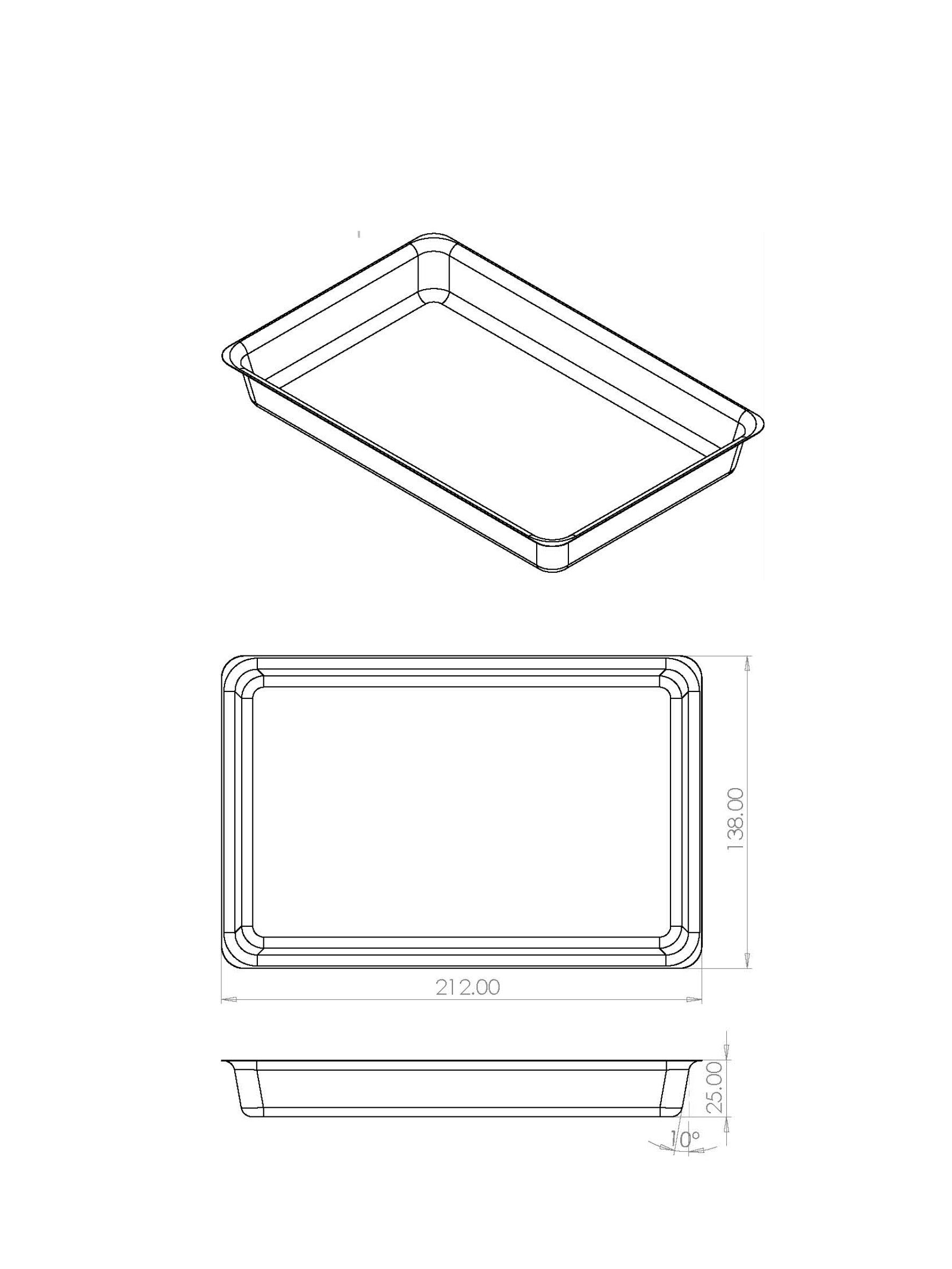

A rigid reusable Recycled Carbon Fibre tray which is lightweight and gives the products it's form. This container shouldn't come into contact with the food itself but should be food safe.

DEVELOP

Design Language

Ideation

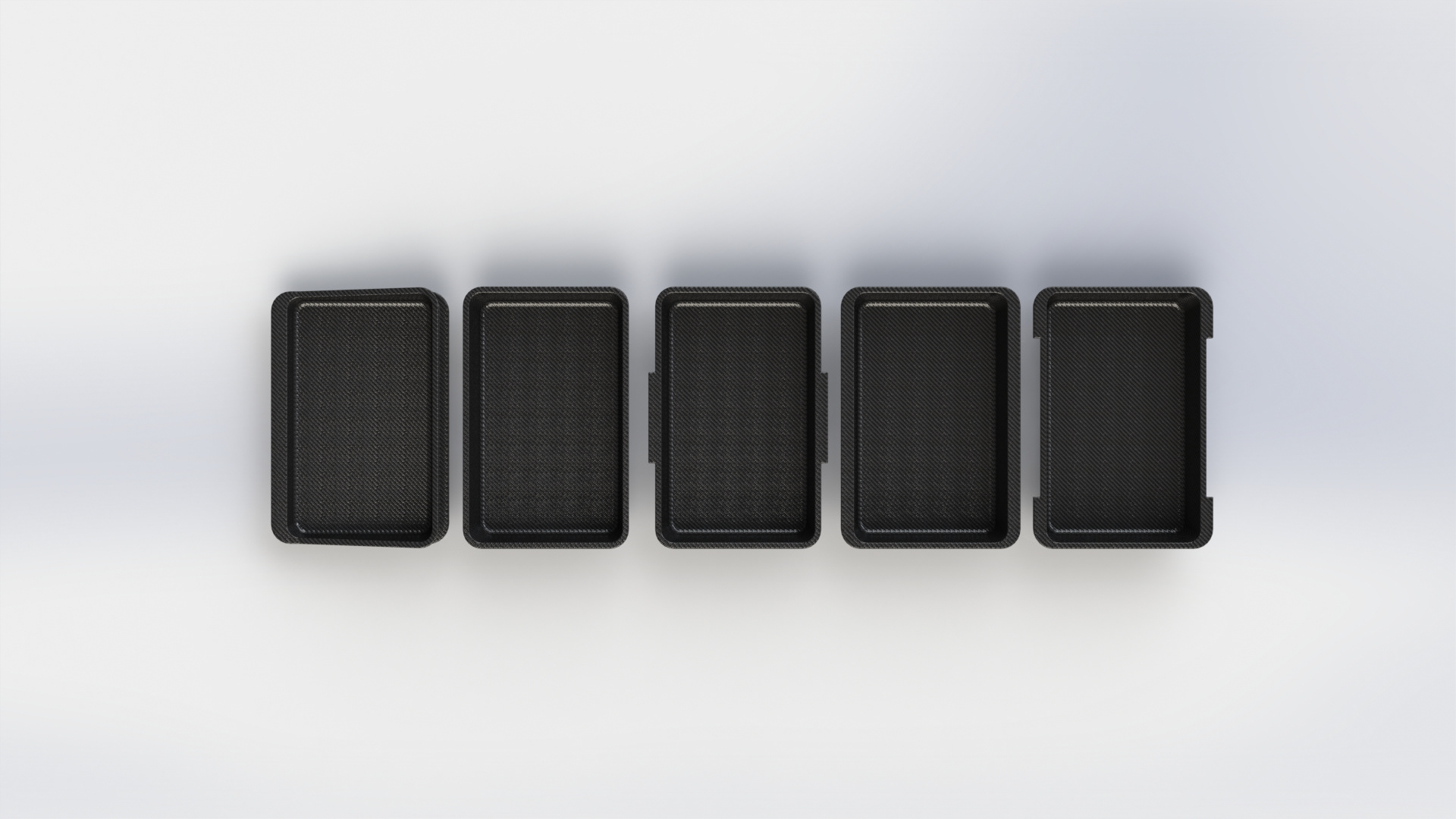

Concepts were generated in order to consider a large amount of possible designs within the specified design direction. A number of different forms and textures were also generated, informed by the design language mood board.

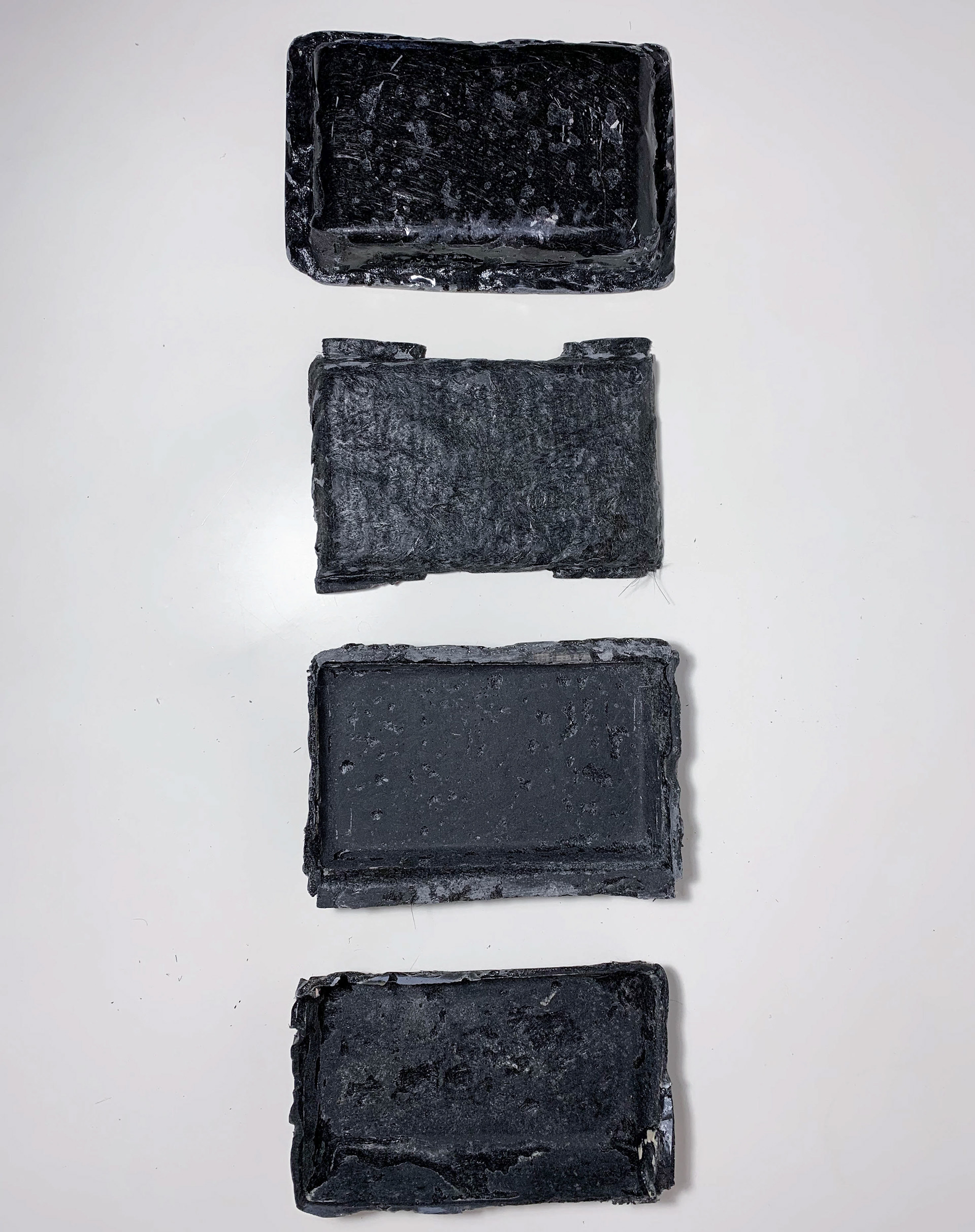

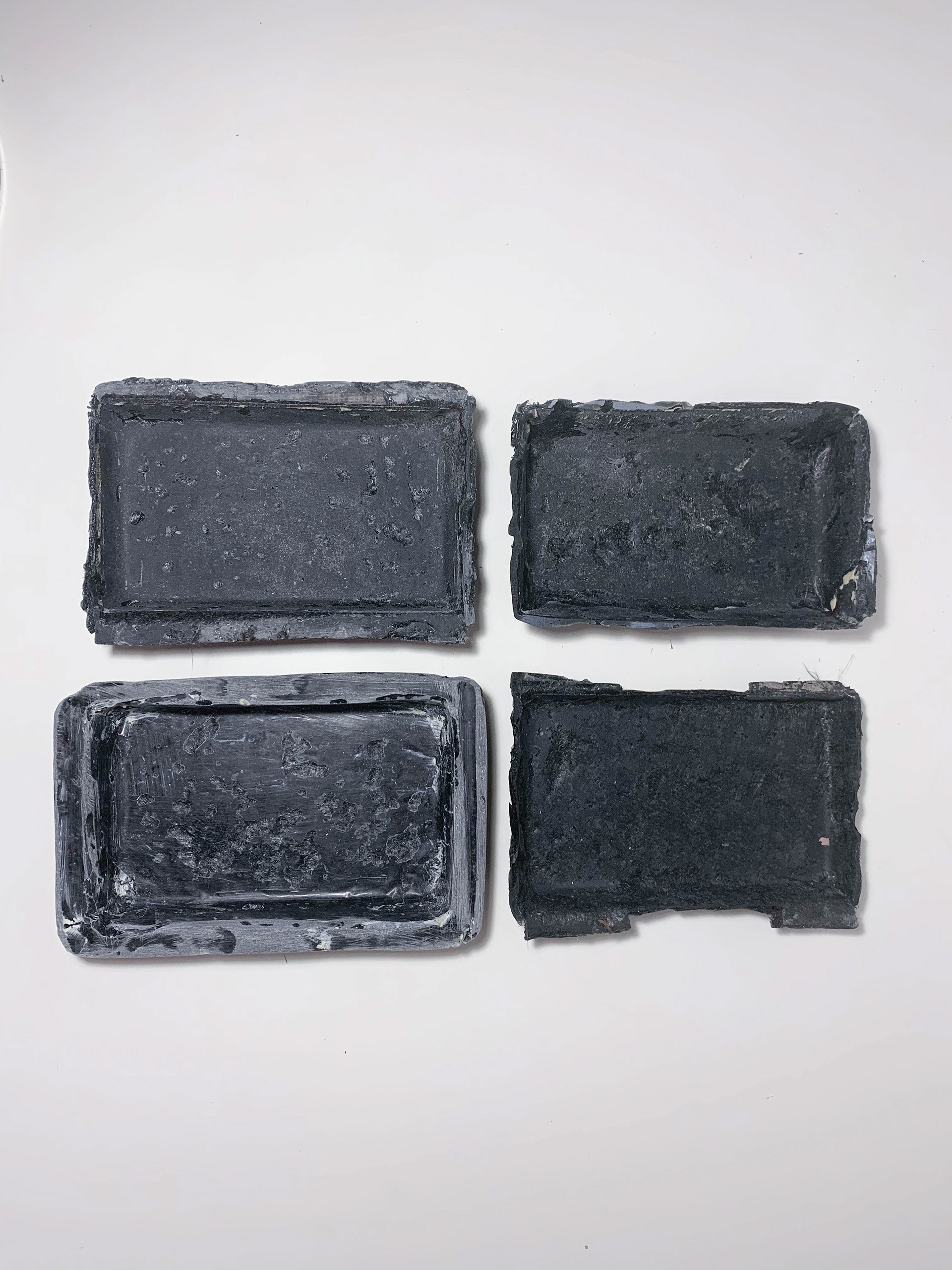

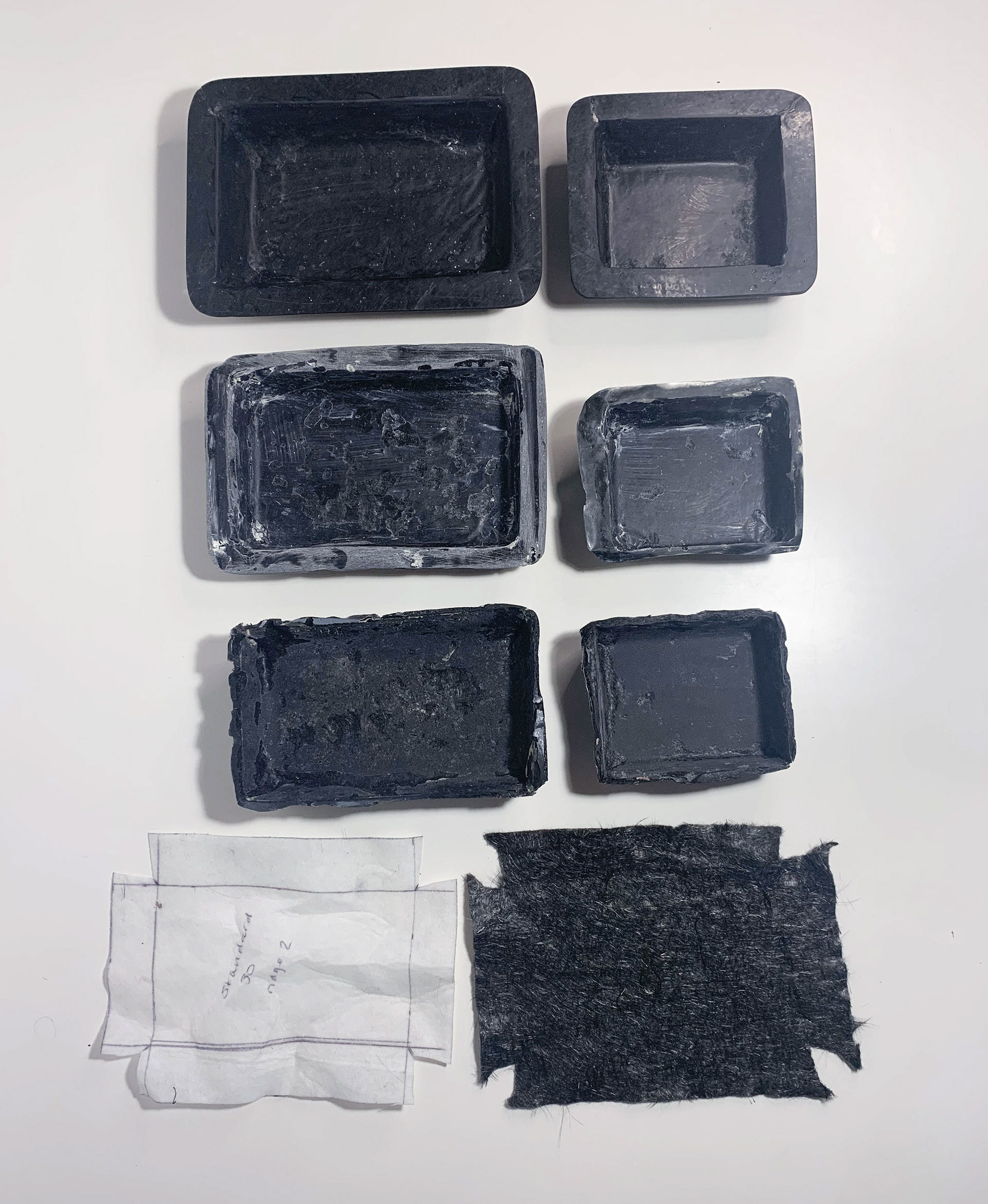

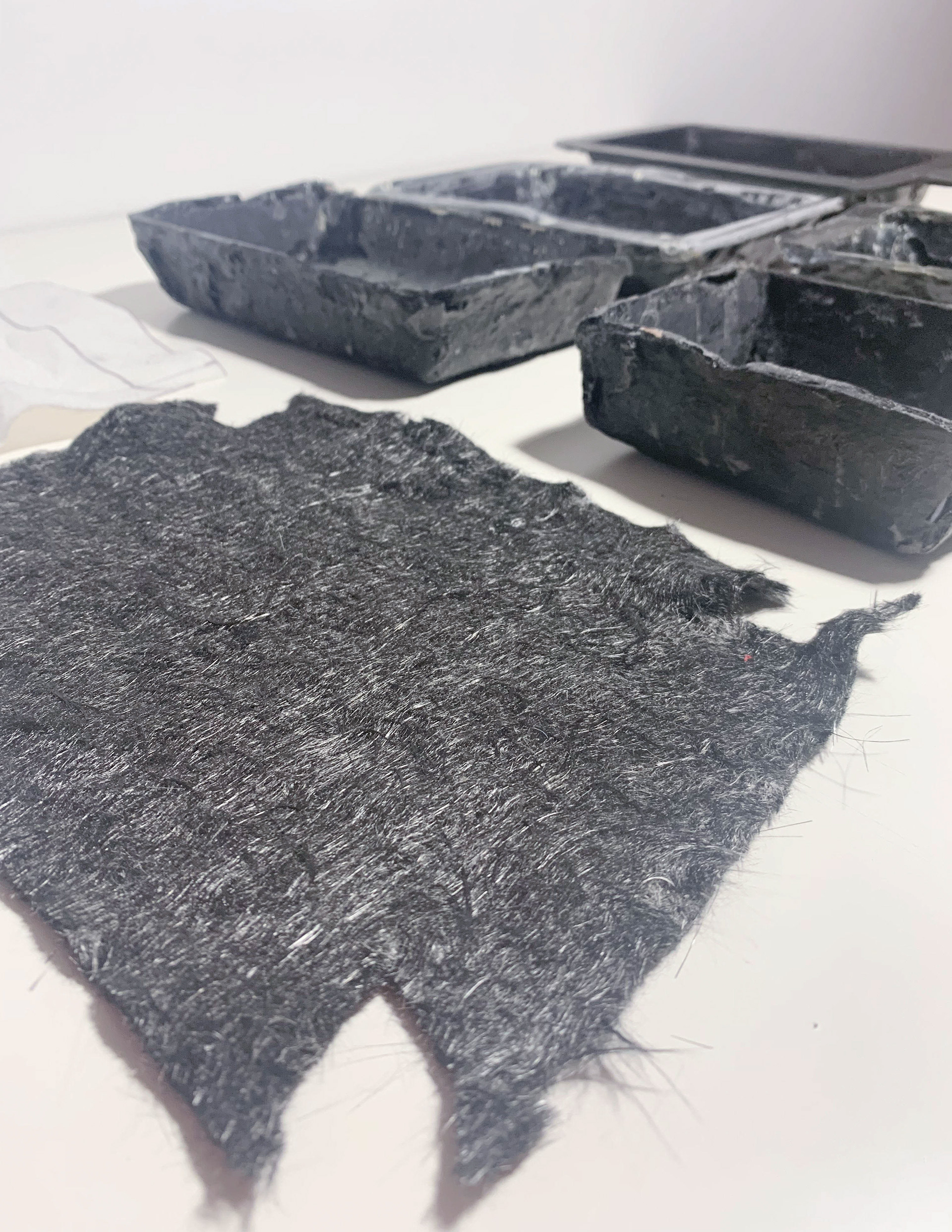

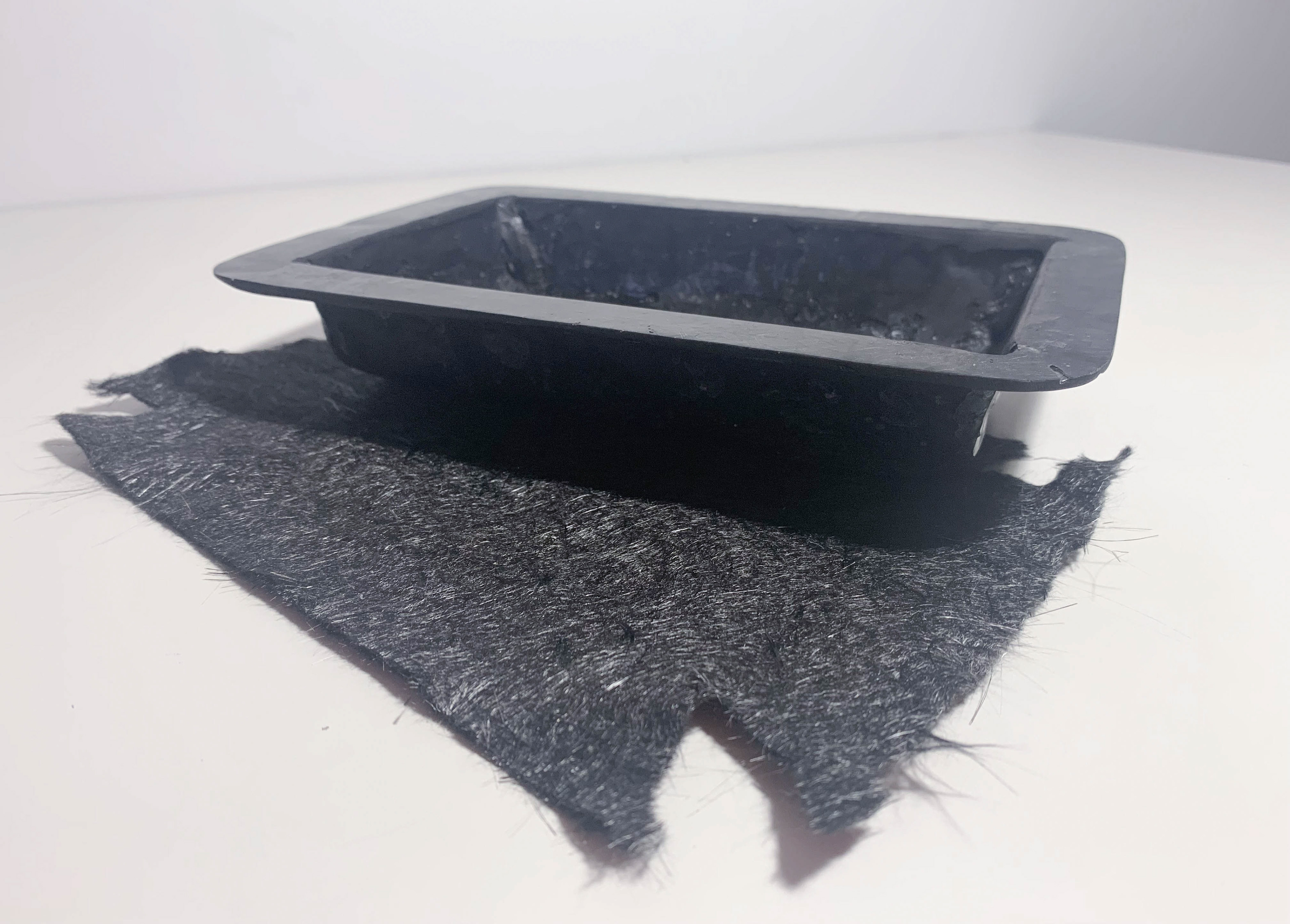

Concepts were refined and developed through the use of sketches, CAD and prototyping with Recycled Carbon Fibre.

Prototyping with Recycled Carbon Fibre was carried out in less than ideal conditions during the initial pandemic lockdown in 2020. However, I was successful in illustrating the range and breadth of concepts for this project and gaining experience with moulding composite materials such as Recycled Carbon Fibre.

To analyse the prototypes produced a series of expert and user interview studies were conducted.

Firstly, the prototypes were reviewed with the industry experts that had previously aided the market analysis stage.

Secondly, a study with a group of frequent flyers was conducted in order to determine the most appropriate form to move forward with.

The studies provided solid insight into the desired form semantics of the project and crucially, insight into the most beneficial insert material from a sustainable design perspective.

Final Prototype

Product Service System

DELIVER

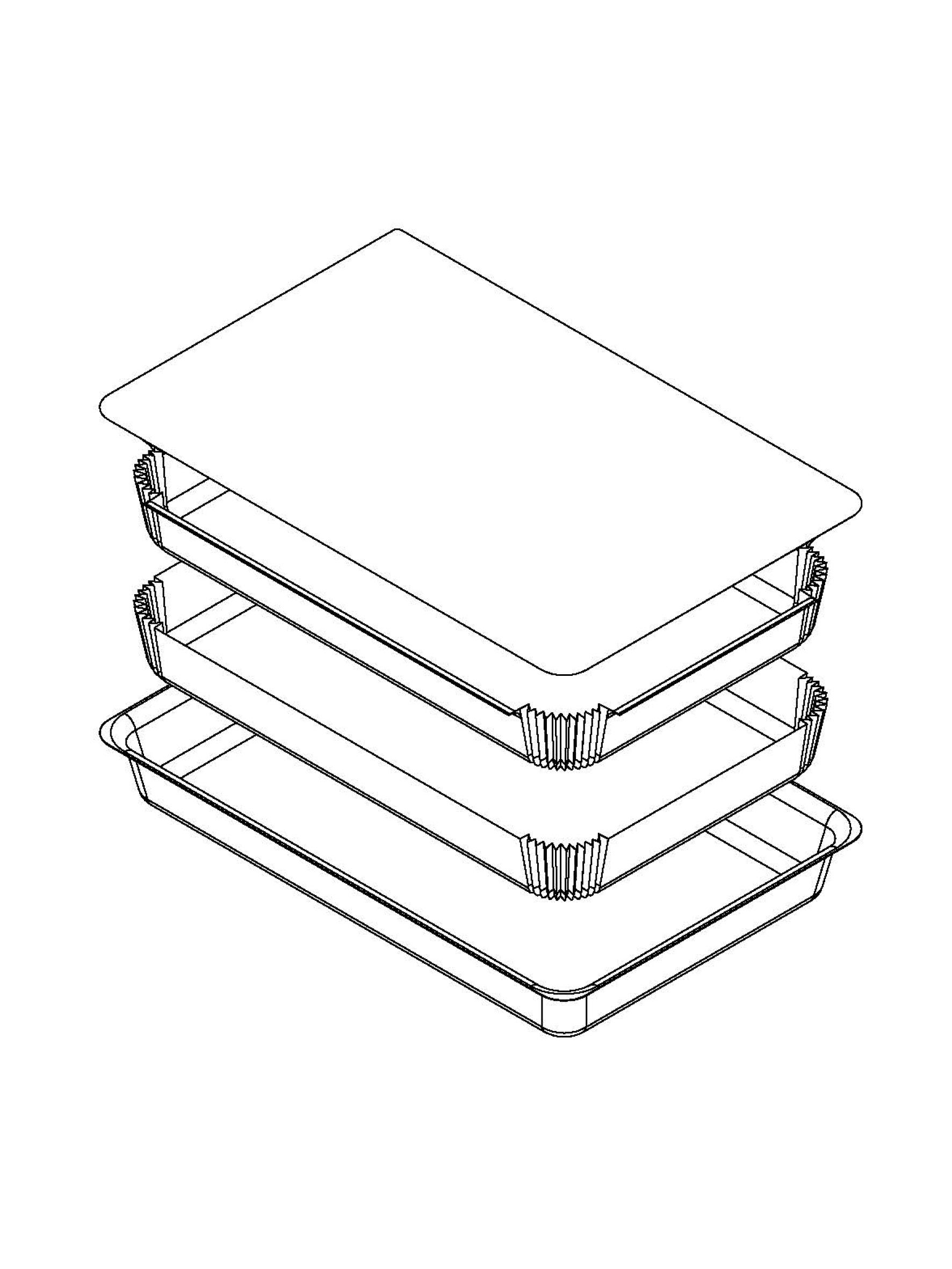

Full meal package

Recycled carbon fibre dishes

Typical meal service

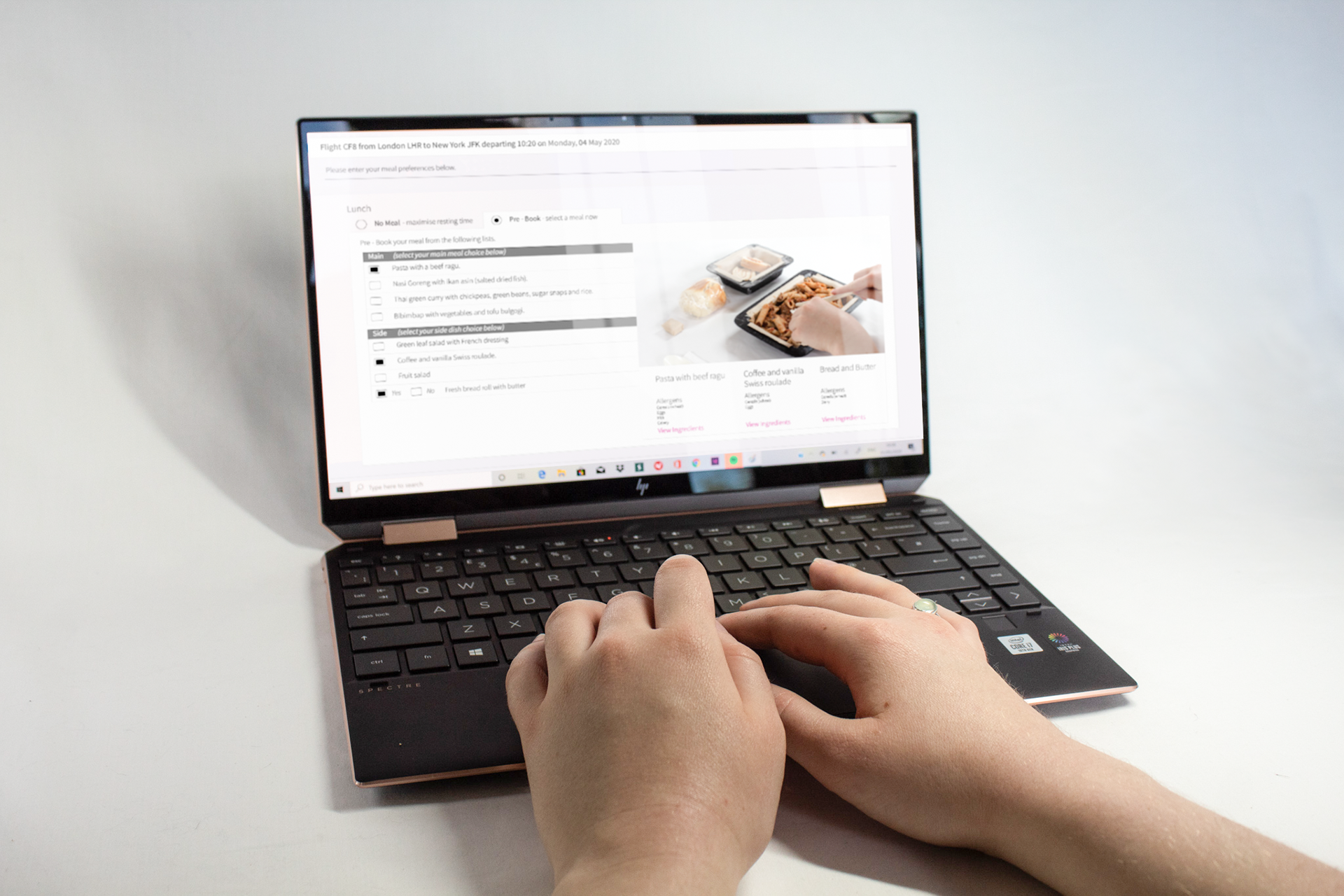

Pre-booking service interaction

Materials were chosen to optimise functional use within strict international disposal regulation whilst providing an enhanced user experience. The reusable recycled carbon fibre dish is ultra-lightweight and designed for incidental food contact and to be washed and reused. Compostable film and paper inserts hold the food and are designed to optimise single use environmental efficiency.

Packaging materials

Exploded view of the meal dish

By removing the need for a meal tray, the meal package is shown to dramatically reduce trolley space requirements and thus decrease weight thereby improving flight fuel efficiency and financial savings for airlines. The design could reduce meal weight by 86% per passenger and carbon output by 581kg/CO2 per 1000 meals when analysed against recent industry statistics. This translates to potential annual savings of £7.1-53million for an airline.

This project was conducted as the Final Year Major Project at Brunel University during the 2019-2020 academic year.

The project is currently featured on the New Designers website.

Want to find out more?

Get in contact